All Your PBS & Tank Needs In One Place!

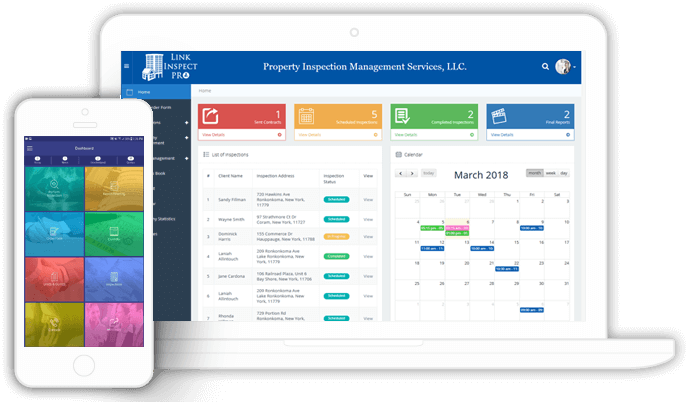

Inspector Network

Digital Inspections

When inspections are conducted, samples taken, or other information gathered, these procedures must be conducted in a manner (for example, using proper “chain of custody” procedures) that will produce evidence admissible in an enforcement proceeding, or in court.

When an UST system is temporarily closed for more than 12 months, owners and operators must permanently close the UST system if it does not meet either performance standards.

Metal piping that routinely contains regulated substances and is in contact with the ground must be cathodically protected in accordance with a code of practice developed by a nationally recognized association or independent testing laboratory.

To prevent spilling and overfilling associated with product transfer to the UST system, all existing UST systems must comply with UST system spill and overfill prevention equipment requirements.

Release Detection Methods

Product Inventory Control

Must be conducted monthly to detect a release

Manual Tank Gauging

Tank liquid level measurements are taken at the beginning and ending of a period. A release is suspected if the variation between beginning and ending measurements exceeds the weekly or monthly standards.

Tank Tightness Testing

Must be capable of detecting a 0.1 gallon per hour leak rate from any portion of the tank that routinely contains product.

Vapor Monitoring

Testing or monitoring for vapors within the soil gas of the excavation zone.

Groundwater Monitoring

Testing or monitoring for liquids on the groundwater.

Interstitial Monitoring

Interstitial monitoring between the UST system and a secondary barrier immediately around or beneath it may be used, but only if the system is designed, constructed, and installed to detect a leak from any portion of the tank that routinely contains product

Statistical Inventory Reconciliation

Release detection methods based on the application of statistical principles to inventory data.